Protective clothing plays a crucial role in safeguarding workers from hazardous substances and maintaining their safety in various industries. Various types of work clothing are available to protect workers from hazardous substances. There are different Type 5 and Type 6 CE-certified protective clothing on the market. Some of them have the best economic option, while others claim better protection feature. Users shall therefore make an extra effort to find an appropriate protective clothing among a wide range of options. Are there any tips to choose which protective clothing is the appropriate one for you?

When choosing appropriate protective clothing, there are several tips that can help you make an informed decision. Here are some factors to consider:

There are 2 facts below that you should first know before selecting appropriate Type 5 and Type 6 protective clothing.

Protection Purpose

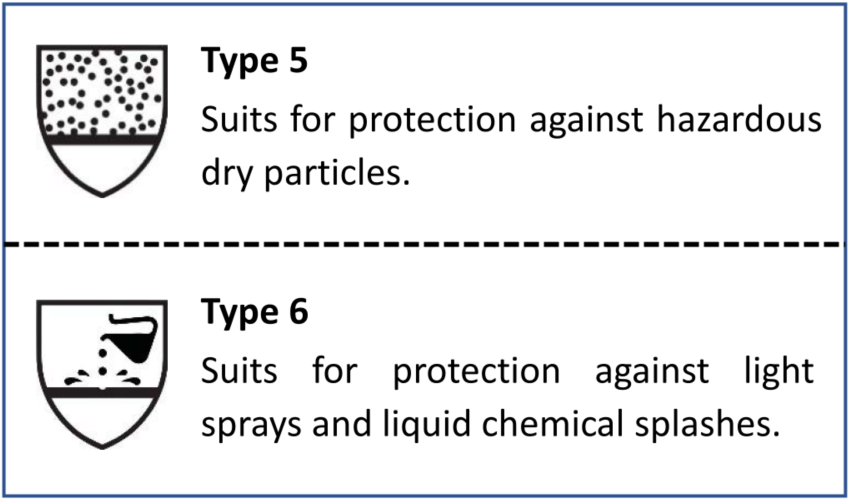

This is the essential part. When you first select Type 5 and Type 6 protective clothing, do you know that Type 5 and Type 6 certifications are applied for different protection purposes and scenarios? A quick introduction to these 2 certifications is provided below.

Type 5 Certification: Dry Particle Suits

Based on Regulation EN ISO 13982-1:2004 + A1:2010, the performance requirements for chemical protective clothing include full body protection against airborne solid particles.

Type 6 Certification: Reduced Spray Suits

Based on Regulation EN 13034:2005 + A1:2009, the performance requirements for chemical protective clothing involve limited protection against liquid chemicals.

Certifications of Type 5 and Type 6 are utilized for different protective purposes and the coverage of protective clothing. A Type 6 coverall is more suitable when dealing with a potentially hazardous liquid spray environment. On the other hand, a Type 5 coverall should be chosen when the environmental risk is associated with harmful particulate matter.

1. Fabric Structure

The fabric used for protective clothing is different in order to obtain protection for different purposes. In Type 5 and Type 6 certified protective clothing, there are two common fabric options in the market, one is Multi-layer SMS fabric, while the other is PP nonwoven with a Laminated Film.

The Multi-layer SMS fabric is a good choice for the protection of particulates. It has minimum 3 layers, and the middle layer, which provides good particulate filtration is known as melt-blown. The fabric also usually provides good air permeability. For the wording SMS, it is the combination of fabric structures, which is Spunbond (S), Melt-blown (M) and Spunbond (S). Some suppliers may offer different combinations, namely SMMS or SMMSSMS. But after all, it is the melt-blown layer provides filtration features on hazardous particulates.

The other common fabric in the market is “Laminated Film on PP nonwoven”. With the microporous film, it provides protection against liquid or fluid penetration, such as water drip, mud, liquid spray or splash. It usually provides better protection for both particulate and liquid hazards compare with SMS fabric. Depending on the film formula and material technology, not only as a liquid barrier, while the microporous film also let the air or moisture can go through.

Comparison between Multi-layer SMS and laminated film:

| Features | Multi-layer SMS | Laminated Film |

|---|---|---|

| Material | Spunbond-Meltblown-Spunbond (SMS) fabric | Multiple layers of film laminated together |

| Protection | Provides barrier against particles | Provides barrier against particles and liquids |

| Breathability | Relatively breathable | Less breathable |

| Comfort | Lightweight and comfortable | Can be less comfortable, depending on the thickness |

| Durability | Durable | Generally less durable than SMS |

On the other hand, if you are primarily concerned with limited liquid spray risk and hazardous particles, a multi-layer SMS fabric coverall may be suitable for you as it provides a breathable wearing experience. However, based on the above comparison chart, protective clothing made from laminated film fabric is a superior choice for protection against both liquids and particles, particularly in situations where the risk is in a more liquid form.

Additional Certifications

In addition to particulate and liquid protection, some additional protection marks may be identified on protective clothing. To solve these ever-changing situations in the workplace, here are several additional certifications needed to be attended to.

1. EN 14126:2003 Against Biological Hazards

It is a key standard for medical and disease control purposes in the workplace. The standard defines a set of specifications that requires 5 methods of testing to measure the fabric. These 5 different tests are included in the certification, and 4 out of 5 tests are tested in liquid form. Most SMS products cannot meet this standard. Only laminated film products are available.

ISO 16603: Resistance to penetration by blood/fluids

ISO 16604: Resistance to penetration by blood-borne pathogens

ISO 22610: Resistance to wet microbial penetration

ISO/DIS 22611: Resistance to liquid aerosol penetration

ISO 22612: Resistance to dry microbial penetration

EN 1073-2:2002 Against Radioactive Contamination

The standard has been developed to be applied to the nuclear industry without protection against ionizing radiation. With the whole suit particle protection level, the inward leakage test determines the barrier efficiency of the suit when the defined particulate size is challenged.

EN 1149-5:2018 Anti-Static

The standard specifies a set of requirements and test methods for assessing the protection of the fabric against static electricity or decay. The anti-static ability can be added to both types of fabric structures. The electrostatic resistance is required when the wearer is exposed to conditions where the sparks could cause explosions or ignition.

DIN 32781:2010 Against Pesticides

The test standard applies to chemical penetration, fabric strength and ergonomic criteria. It includes EN 14786, which simulates liquid drug spraying. 5 different pesticides are tested to ensure full safety against pesticides, including U46-D-Fluid (BASF), Pirimor Granulat (Syngenta), Amistar (Syngenta), Betanal Expert (Bayer) and Folicur (Bayer). Some laminated film fabric coveralls in the market do meet and offer this standard for those agriculture application users.

Choose an Appropriate Type 5 and Type 6 Protective Clothing requires careful consideration of the factors discussed above, including additional certifications.

Laminated Film protective clothing offers superior protection against both liquids and particulates, making it suitable for most working conditions. However, if breathability is a major concern and the work risk assessment does not demand premium protection against liquids and particulates, Multi-layer SMS fabric may be more suitable in such cases.

It is important to note that fabric structure alone should not be the sole criterion for selecting protective clothing. Additional certifications are equally important. Understanding the specific risks involved in your workplace before entering is crucial. This knowledge will enable you to choose an appropriate coverall that ensures your safety and allows you to return home safely.

Contact Us

SEOkeywords

Type 5/6 Protective CoverallsPurchase Medical and Surgical GownsNonwovens ManufacturingDisposable surgical drapes for the operating roomTypes of Surgical DrapesHow to Choose an Appropriate Type 5 and Type 6 Protective ClothingProductsDisposable Surgical Gown ManufacturerEverything You Need to Know About Spunbond NonwovensDisposable Surgical DrapesDisposable Surgical Gowns